看了SET 系列双螺杆挤压造粒机的用户又看了

留言询价

留言询价 电话询价

电话询价

虚拟号将在 180 秒后失效

使用微信扫码拨号

SET 系列双螺杆挤压造粒机

SET Double-Screw Extruding Pelleter

SET 系列双螺杆挤出造粒机,挤出形式有前出料和侧出料两种。经混合、捏和的湿物料或低软化点 ( 一般小于 50℃ ) 物料在螺杆输送、挤压作用下,从机头开孔模板挤出,再经过干燥或冷却得到颗粒成品,从而实现将粉状产品改变为均匀的颗粒产品的目的。颗粒形状为圆柱状,成品颗粒直径可由模板开孔孔径调节和控制:侧出料为 0.7-2.0mm,前出料为 1.5-12mm,成粒率≥95%。

◆

The machine of front and side for material to be extruded out. Wet material or material with low melting point (general means<50℃ ) after being kneaded and mixed shall be extruded out

from mould plate at the head of the plant due to being conveyed and pressed by screws,

and then be dried or cooled to form end products of particles so as to complete the course

of changing material from powder to particle. The shape of grain is cylindrical. The diameter

of end grain can be chosen and controlled by means of changing the diameter of holes in the

mould plate: for side type is 0.7-2.0 mm, for front type is 1.5-12 mm. The rate of end product

is equal to or more than 95% .

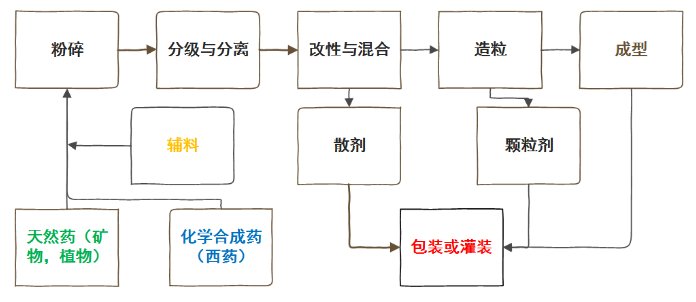

◆ 广泛适用于橡胶助剂、食品添加剂、塑料助剂、催化齐、农药、染料、颜料、日化、制药行业需造粒的产品。

◆

The plant is widely applied to material needs granulating such as rubber auxiliar, food additive, plastic auxiliary,

catalyzer,agrochemicals, dye, pigment, daily chemicals, medicine etc.

暂无数据!

干法制粒是在传统湿法混合制粒基础上发展起来的一种新的造粒工艺。整个造粒过程无需任何中间体和添加剂,也不需后续加工处理,可有效控制溶解度、孔隙率和比表面积,可以制备湿法制粒工艺比较难做的粉体物料,具有压

2020年4月,连花清瘟胶囊、颗粒获批新增新冠肺炎适应症,连花清瘟在细胞水平对新型冠状病毒显示出抗病毒与抗炎效果,为新型冠状病毒感染的治疗带来了希望。但不少人在胶囊和颗粒之间犯了迷糊,有何区别呢?其实

常州市森茂机械设备有限公司在刚刚结束的VIV QINGDAO 2021亚洲国际集约化畜牧展览会(青岛)现场进行的产品展示。 展会期间,企

SET 系列双螺杆挤压造粒机的工作原理介绍?

SET 系列双螺杆挤压造粒机的工作原理介绍? SET 系列双螺杆挤压造粒机的使用方法?

SET 系列双螺杆挤压造粒机的使用方法? SET 系列双螺杆挤压造粒机多少钱一台?

SET 系列双螺杆挤压造粒机多少钱一台? SET 系列双螺杆挤压造粒机使用的注意事项

SET 系列双螺杆挤压造粒机使用的注意事项 SET 系列双螺杆挤压造粒机的说明书有吗?

SET 系列双螺杆挤压造粒机的说明书有吗? SET 系列双螺杆挤压造粒机的操作规程有吗?

SET 系列双螺杆挤压造粒机的操作规程有吗? SET 系列双螺杆挤压造粒机的报价含票含运费吗?

SET 系列双螺杆挤压造粒机的报价含票含运费吗? SET 系列双螺杆挤压造粒机有现货吗?

SET 系列双螺杆挤压造粒机有现货吗? SET 系列双螺杆挤压造粒机包安装吗?

SET 系列双螺杆挤压造粒机包安装吗? 手机版:

手机版: